Magnetic Fluid Conditioning

Affects the physical properties of the paraffin and scale molecules to keep them in solution

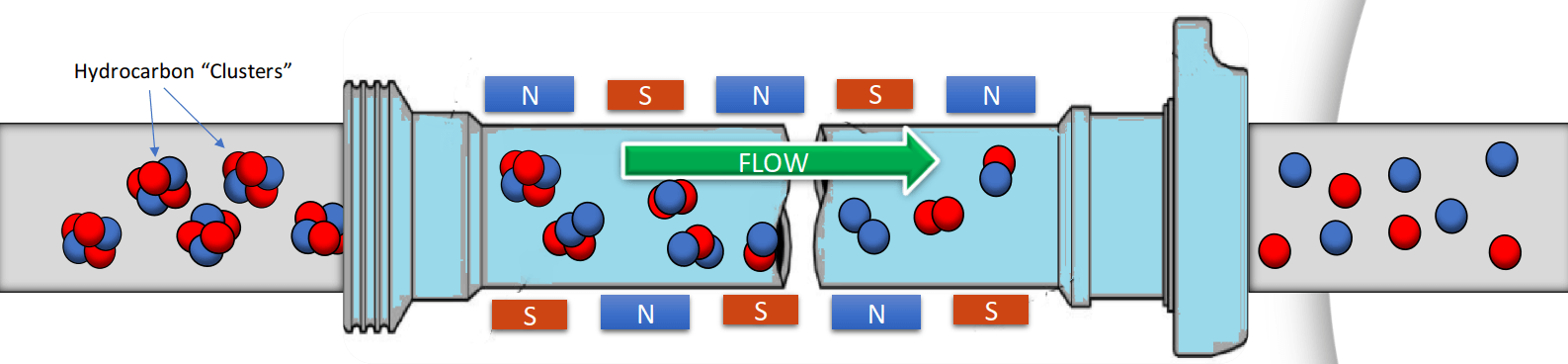

How It Works

Flo-Rite’s unique design passes the production through an annulus to insure uniform velocity and magnetic treatment of all fluid passing through the MFC. The Flo-Rite design exposes all fluid to many alternating magnetic fields. Failures by competitive tools reflect inherent design deficiencies in the strength, number of magnetic fields; and/or inadequate velocity. The design of the Flo-Rite MFC makes it superior in terms of effective and reliable performance. We treat the Fluid…Not the pipe.

Flo-Rite’s Magnetic Fluid Conditioners are constructed out of high-grade stainless steel. Downhole MFCs for 2-3/8” and 2-7/8” tubing are attached as part of the string right above the slotted sub. The MFCs used on insert pumps, bumper springs, and wireline application have an OD of 1.66” to fit through any profile or seat nipple with standard fittings at both ends for attaching to the bottom seat cups. Standard flowline and transfer pump MFCs are fitted with 2” NPT threaded ends, but can be manufactured for any size flange or connection that may be needed. Size of custom MFCs is determined by flow rate. Flo-Rite MFCs have no moving parts, they are maintenance free to the customer, and have no outside power requirements. The permanent rare earth magnets that we use in our construction have an indefinite lifetime.

The paraffin molecules align their poles with the magnetic field – it changes the electrons rotation and translation patterns which in turn changes their orbital angular momentum. This leads to a disturbance in the crystal agglomeration process. Hydrocarbons form clusters and the magnetic fields align the chain making a dipole relationship with itself which de-clusters, and reduces size of crystals: This prevents paraffin deposition and actually develops a repulsion between the molecules changing the rheological and morphological properties.

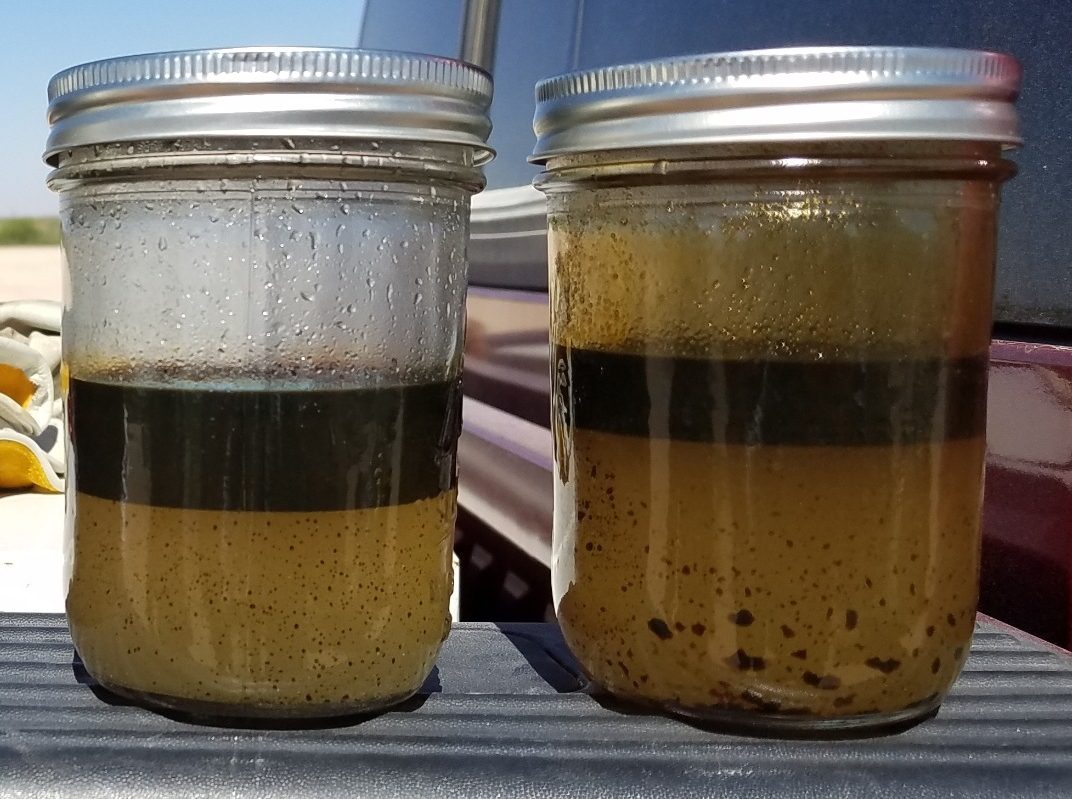

Before FLO-RITE MFC Install:

Initial

Picture before treatment of any kind was applied to a Wolfcamp flowline. A hot oil treatment cleaned the flowline, however, in just 10 days, buildup was rapidly occuring once again.

After FLO-RITE MFC Install:

Week 1-20

Following the installation, the buildup began dissipating. After 10 weeks, walls are visible with no other hot oil treatments. After week 20, without any hot oil treatments, the flowline is virtually free of any buildup