Magnetic Fluid Conditioning

Treats 100% of production using our patented design

Oil Field Products

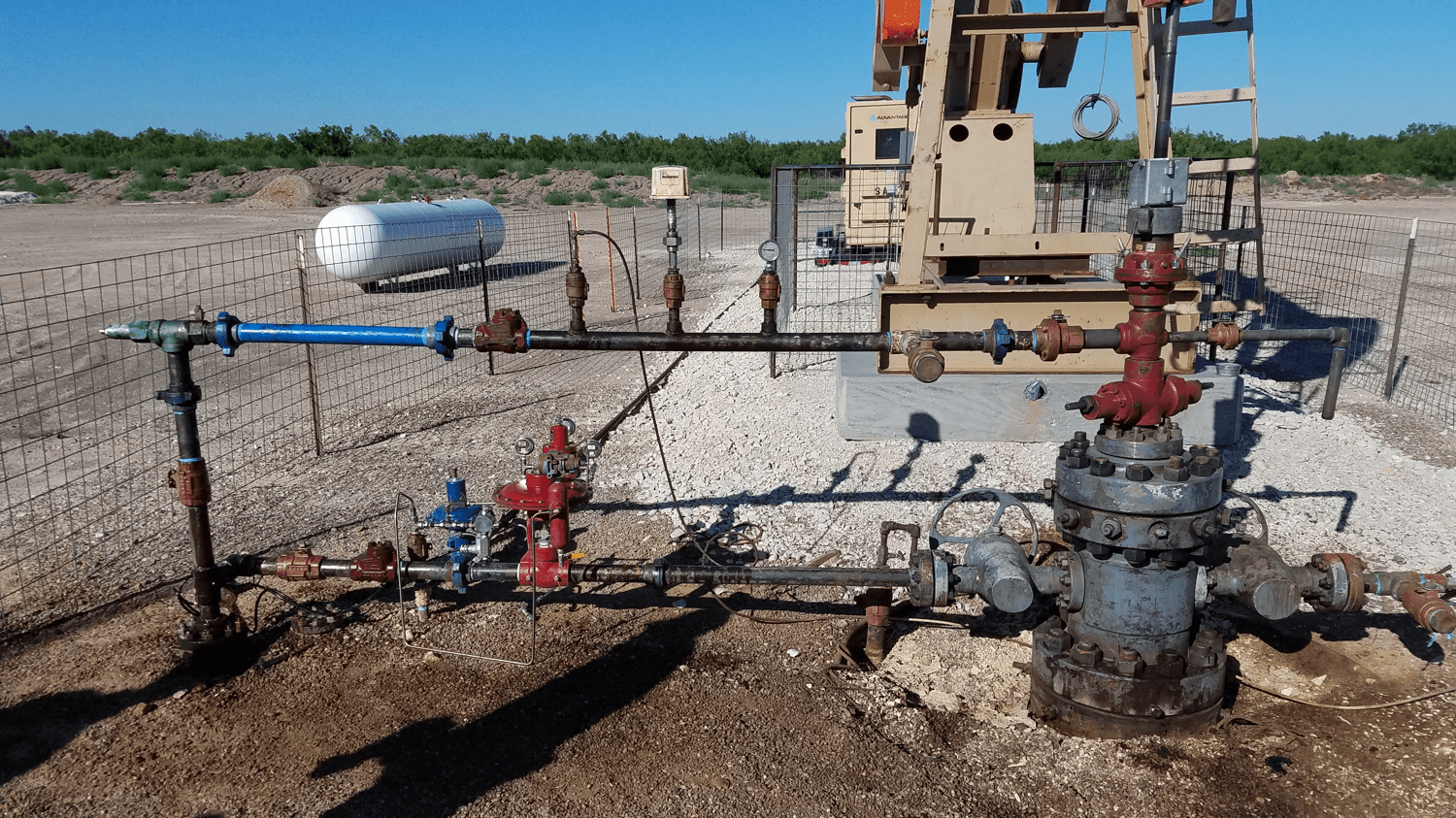

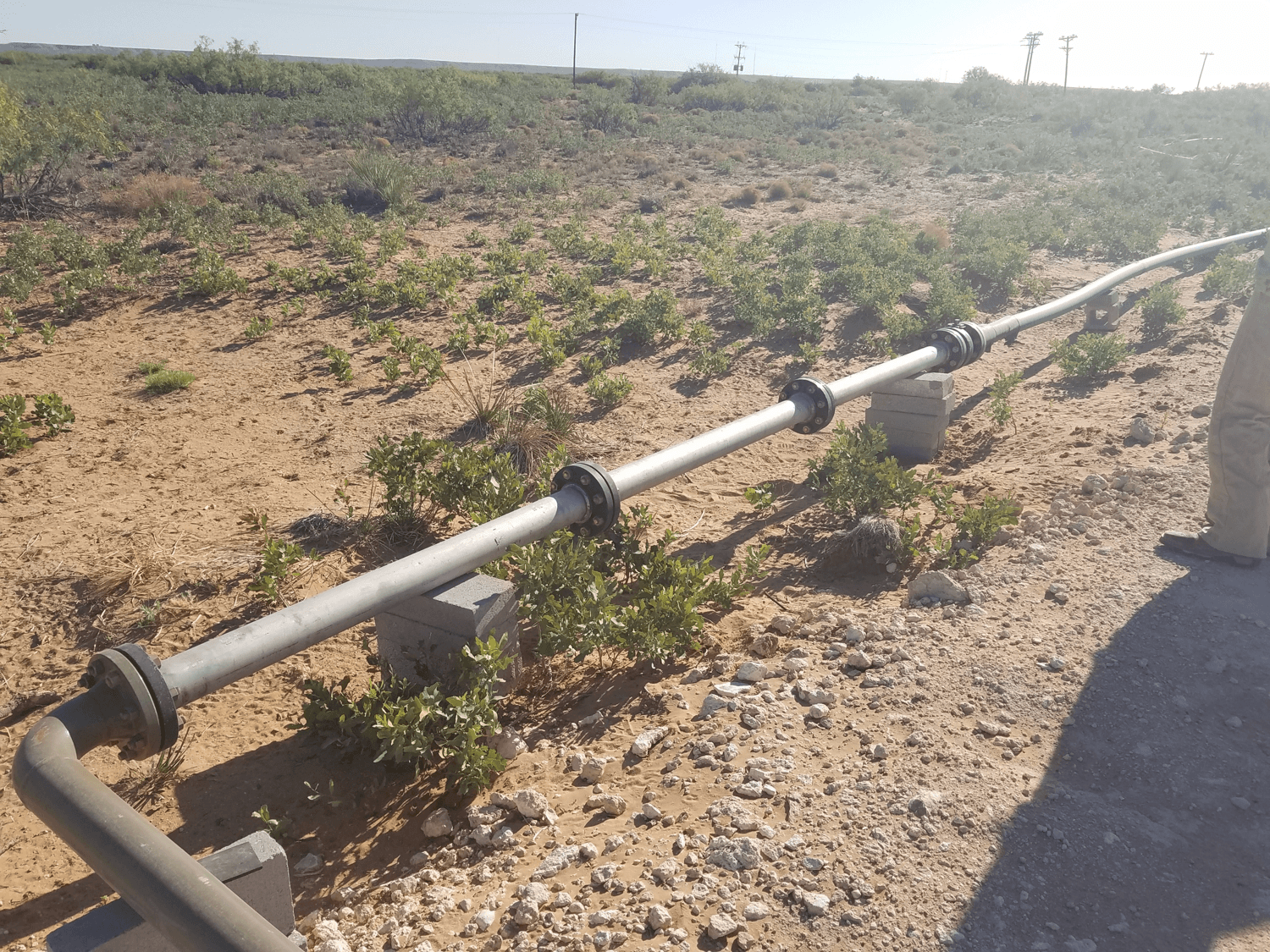

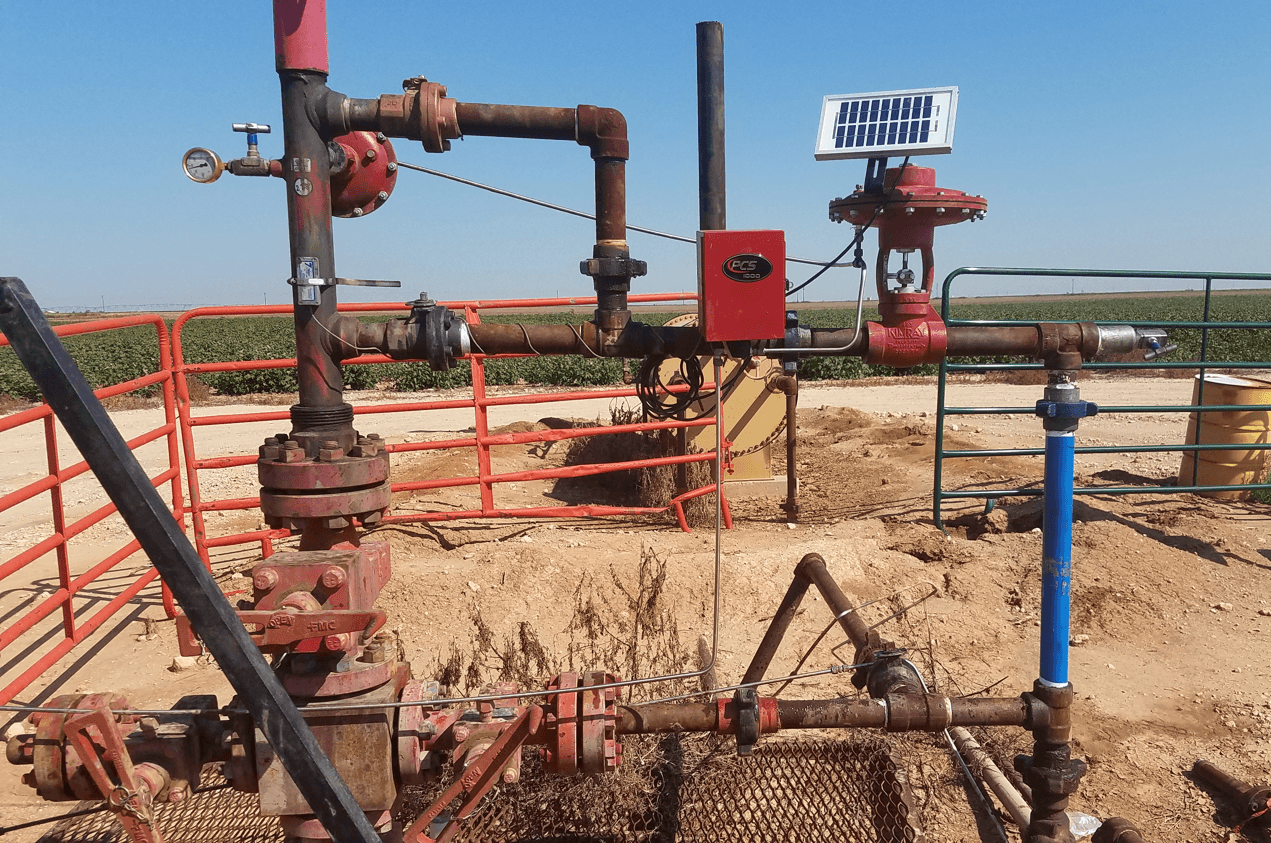

Flo-Rite has U.S. Patents issued for the different applications that we offer, both downhole and on surface. Downhole Magnetic Fluid Conditioners (MFCs) can be installed in the tubing string, under an insert pump or plunger spring, or can be deployed via wireline. On surface the MFCs can be installed in the flowline, at the header, on the discharge side of a circulating pump, or in any other area in the system as needed.

Flo-Rite’s Magnetic Fluid Conditioners come in standard oil field sizes but since all MFCs are manufactured in house, we can design and build an MFC for most applications. Our paraffin treatment system also has a concept patent and has been tested in hot and cold temperatures with the same fantastic results.

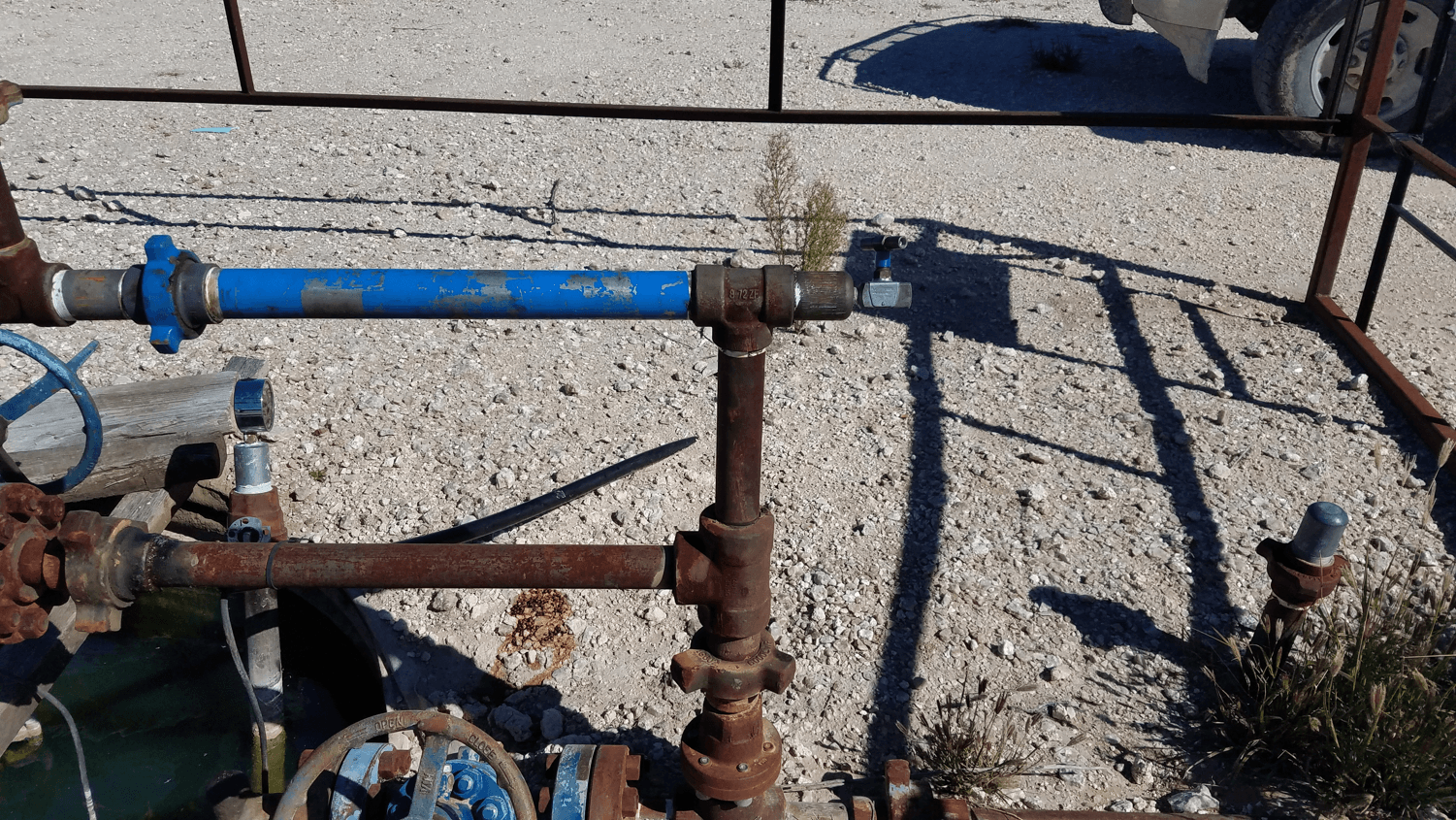

MFC is an inline tool designed to pass fluid at high velocity through strong alternating magnetic fields. The MFCs reduce paraffin and mineral scale from depositing on production tubing and surface facilities. No external power is required, so Flo-Rite MFCs can be utilized in the most remote locations that have no electrical power. By employing permanent rare earth magnets with an indefinite life, our MFCs are virtually maintenance free.

To get the full effect of the MFC treatment, correct placement is vital. Installing an MFC at the bottom of the tubing string, rod pump, bumper spring, or deployed via wireline (into a seat nipple, collar stop, lock mandrel, etc..). This ensures that the entire system from the bottom of the well all the way to the tank battery is treated.

If we’re unable to install an MFC downhole, a surface MFC can be installed to treat the flowlines and surface equipment. To get the most out of the treatment, we recommend installing the MFC at the beginning of the flowline usually at the wellhead. While our standard flowline MFC is 2” threaded NPT, they can be designed for any size with threads or flanges.

By reducing paraffin and scale buildup in tubing and pumps, cleanouts, repairs, and other treatment costs are greatly reduced or eliminated. Production rates can be stabilized at higher levels without restriction from rapid paraffin buildup. Costly chemical treatments, additional mechanical treatments, down time, and additional man hours are significantly reduced and some can be eliminated completely.

Economic Benefits - Paraffin Control

Flo-Rite units can be installed downhole in wells with any kind of lift system:

- Natural Flow

- Rod Pump

- Electric Submersible Pump

- Hydraulic Pumps

- Gas Lift

- Plunger Lift